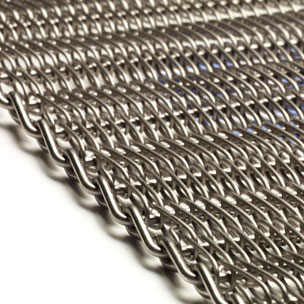

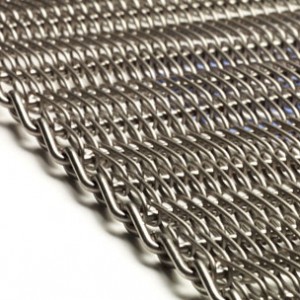

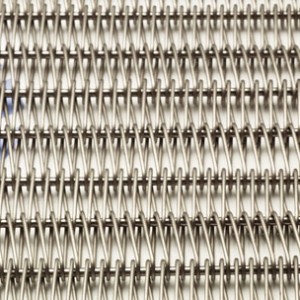

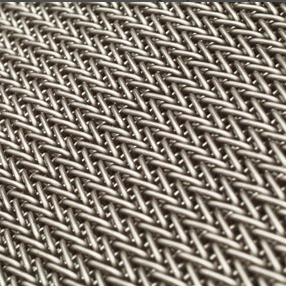

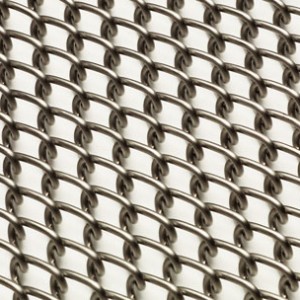

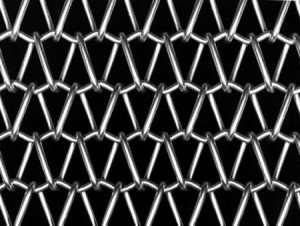

I-Flat Spiral yakhiwe ngokutshintshana kwezikhonkwane ezijiyileyo zesandla sasekhohlo nasekunene, ezilukwe kunye kwaye zidityaniswe ngokudityaniswa kweentonga ezinqamlezileyo.

Uyilo olutshintshanayo lwe-Flat Spiral's mesh lunceda ukunciphisa iingxaki zokulandela umkhondo ezibangelwa kukujika kwebhanti ukuya kwelinye icala.Imingxuma emincinci ekhoyo kulwakhiwo lwebhanti ibonelela abasebenzisi bokuphela ngomphezulu ogqithisayo osicaba olungele imveliso etyekele ekutyibilikeni kwiidizayini zemesh ezivuleleke ngakumbi.

Ibhanti inokubonelelwa nge-welded, i-laddered okanye i-hook edge kwaye isetyenziswe kwi-friction drives ye-conveyor layouts.I-Flat Spiralcan nayo inokubonelelwa ngeencam zekhonkco xa uqwalaselo oluhle lokuqhuba lufuneka.I-Flat Spiral ixhaphake ukubonelelwa kwiBakala 304 iStainless Steel, nangona kunjalo, ezinye izinto zokufunda ziyafumaneka xa uzicelile.

Ukufumaneka komda

Umda oNyuliweyo (LD) - umnatha kuphela

I-laddered cross wire igqibezela i-edge esemgangathweni yeebhanti ze-Flat Spiral.Umphetho webhanti ugudile kwaye uvumela ukuguquguquka ngakumbi komphetho webhanti.Ihlala isetyenziswa apho i-welds ayinqweneleki kwisicelo.Ikwasebenza ngokufanelekileyo kwizicelo zobushushu obuphezulu njengoko umphetho weleli ungekho phantsi koxinzelelo olusebenzayo olusetyenziswayo kwaye ngoko ke awufanelwanga kukuqhekeka.

Umda weHook (H) – umnatha kuphela

Ixhaphake kakhulu kunohlobo lwe-laddered edge i-edge ye-hook nayo isetyenziswa rhoqo apho i-welds ayinqweneleki kwisicelo.Kwakhona kukhetho kwizicelo apho izibonelelo ze-welding zingekho.Umphetho webhanti ugudile kwaye uvumela ukuguquguquka komphetho webhanti.

I-Welded Edge (W) - i-mesh kuphela

Eli lungiselelo aliqhelekanga ngakumbi kunokuba ileli okanye i-hook edge njengoko kuncitshisiwe ukuguquguquka phakathi kwekhoyili kunye nocingo olunqamlezayo emiphethweni.Ngokudityaniswa kwee-coil kunye neengcingo ezinqamlezayo akukho ziphelo zocingo ezisikiweyo.

Umphetho wekhonkco oqhutywa ngomnatha

Kunye nesiphelo somnatha ongentla le meshes inokuqhutywa ngamatyathanga asecaleni kusetyenziswa izibonda ezinqamlezileyo ezifumaneka ngeekhoyili zemesh kwaye ke nangona amatyathanga emacaleni omnatha.Iindidi zokugqitywa kweentonga ezinqamlezileyo kumphandle wekhonkco elisecaleni zezi zilandelayo:

Ngewasha edibeneyo

Esi sesona simbo sixhaphakileyo nesinoqoqosho sokugqiba kwibhanti ephethe ikhonkco kwaye siquka i-mesh esembindini ethwalwa ngesixokelelwano ngamatyathanga asemacaleni aneentonga zomthuthi ezinqamlezayo kuzo zombini i-mesh kunye ne-edge chain.Kuxhomekeka kumnatha wocingo olunqamlezileyo lwepitch iirodi ezinqamlezileyo zinokuthatha indawo yocingo olunqamlezayo lomnatha osisiseko.Iintsimbi ezinqamlezileyo zigqitywe kwincam yekhonkco yangaphandle ngewasha edityanisiweyo.

Ngepini yecotter kunye newasha

Nangona uqoqosho oluncinci olu hlobo lwendibano luvumela umthengi okanye abasebenzi benkonzo ukuba bakwazi ukubuyisela amatyathanga e-edge drive xa i-mesh kunye neentonga zisasebenza.Indibano ibandakanya i-mesh esembindini ehanjiswa kwinkqubo ngokusebenzisa amatyathanga asemacaleni aneentonga ezinqamlezileyo zokuthwala kuzo zombini i-mesh kunye ne-edge chain.Iintonga ezinqamlezileyo zigqitywe ngaphandle ngomngxuma ogrunjiweyo ukuvumela ukufakwa kwewasha kunye nephini yecotter.Ikwavumela ukutshintshwa kokulungiswa kwamacandelo ebhanti ngaphandle kwesidingo sokugaya iintloko zentonga kunye ne-weld back together.

QAPHELA: Ukuzinza okukhulu kobubanzi beentonga kwikhonkco yinto eqhelekileyo, apho kunokwenzeka, ukubonelela ngeerodi ezinqamlezileyo ezijikelwe phantsi ukuze zingene kumatyathanga asemacaleni.

Ezinye izitayile ezahlukeneyo zokugqiba komphetho wekhonkco

Ezi ziquka:-

a.Intonga enqamlezileyo edityanisiweyo egungxulwayo ukuya kwisikhonkwane esimgongxo setsheyini esecaleni.Lo ayingomgangatho ukhethwayo kodwa kunokuba yimfuneko apho ububanzi phakathi kwezakhelo ezisecaleni zokuhambisa & namanye amalungu olwakhiwo adala umda apho “iwasha edityanisiweyo” okanye “iwasha kunye nephini yecotter” ayinakusetyenziswa.

b.Intonga enqamlezileyo edityanisiweyo igungxulwe kumngxuma owombiweyo kwiipleyiti zangaphakathi zekhonkco lokuhambisa.

Ngokubanzi amabhanti aqhutywa ngetyathanga ayafumaneka ngezitayile ezi-2 zomphetho wekhonkco:-

I-Transmission Chain - ine-roller encinci

I-chain edge side plate inokuxhaswa nokuba kwi-angle side frame, okanye ngokusebenzisa umzila weprofayili ukuya phakathi kwamacwecwe ecala kunye nenkxaso kwi-roller.Kungenjalo inokuqhuba ngaphandle kwenkxaso yetyathanga apho umnatha uxhaswa kufutshane nomphetho wetyathanga.

I-Conveyor Roller Chain-ine-roller enkulu.

Olu ngqameko lwetyathanga lunokuxhaswa kwi-engile enomphetho osicaba umcu wokunxiba kunye nerola yekhonkco ejikeleza ngokukhululekileyo ecaleni kobude bokuhambisa.Isenzo se-roller ye-chain sinciphisa ukuguga kwekhonkco kwaye sinciphisa ukungqubuzana kokusebenza kweli nqanaba.

Iindlela zokuqhuba

Ukukhuhlana Kuqhutywa

Eyona ndlela ixhaphakileyo yokuqhuba yintsimbi ecacileyo i-parallel driven roller system.Le nkqubo ixhomekeke ekudibaneni kwe-friction phakathi kwebhanti kunye ne-roller ukuqinisekisa ukuqhuba ibhanti.

Iiyantlukwano zolu hlobo lwe-drive ziquka ukulahlwa kwe-roller ngezinto ezifana nerabha, i-friction brake lining (ubushushu obuphezulu), njl njl. ubomi obuluncedo bebhanti.

IChain Edge iqhutywa

Ngale ndibano yebhanti i-pitch yocingo lomnqamlezo we-mesh yebhanti yenziwa ukuqinisekisa ukuba i-chain edge yindawo yokuqhuba kunye ne-mesh yebhanti itsalwa kwisekethe ngamatyathanga.

Ukufumaneka kweMathiriyeli esemgangathweni (iMesh Kuphela):

| Izinto eziphathekayo | Obona bushushu bokusebenza ngocingo °C |

| Intsimbi yeCarbon (40/45) | 550 |

| Intsimbi eGalvanized Mild | 400 |

| IChrome Molybdenum (3% Chrome) | 700 |

| 304 iStainless Steel (1.4301) | 750 |

| 321 iStainless Steel (1.4541) | 750 |

| 316 iStainless Steel (1.4401) | 800 |

| I-316L yeNtsimbi engagqwali (1.4404) | 800 |

| 314 iStainless Steel (1.4841) | 1120 (Kuphephe ukusebenzisa kwi-800-900 ° C) |

| 37/18 Nickel Chrome (1.4864) | 1120 |

| 80/20 Nickel Chrome (2.4869) | 1150 |

| I-Inconel 600 (2.4816) | 1150 |

| I-Inconel 601 (2.4851) | 1150 |