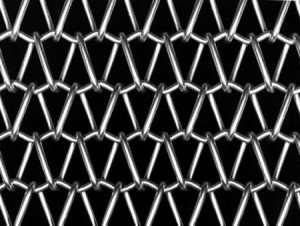

Ikwabizwa ngokuba 'yiCompound Balanced' ibhanti

Iibhanti zeCordweave zeNkampani yeWire Belt zibonelela ngomnatha osondele kakhulu kwaye osicaba kwizicelo apho kuhanjiswa izinto ezincinci kakhulu.I-Cordweave ikwabonelela ngokugqithisela ubushushu obufanayo kwibhanti ngenxa yoxinaniso oluphezulu kunye nomphezulu wokuthwala ogudileyo.Ezi mpawu zenza i-Cordweave ibe lukhetho oludumileyo kwiintlobo ngeentlobo zezicelo, ukusuka kwi-biscuit yokubhaka ukuya ekuhleleni izinto ezincinci zoomatshini.

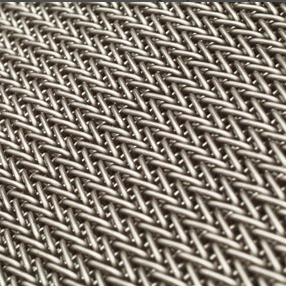

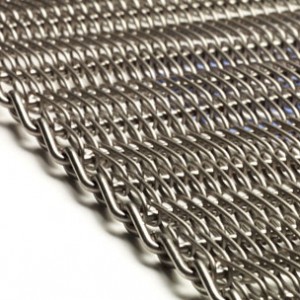

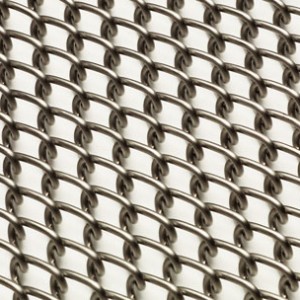

Ekwaziwa ngaphakathi kushishino njenge "Compound Balanced (CB)" ibhanti, ibhanti leCordweave ngokusisiseko libhanti leBalanced Spiral elinemibhobho emininzi kunye neerods ezinqamlezayo kwipitch, ngokufanelekileyo ukudala "ibhanti ngaphakathi kwebhanti".Olu lwakhiwo oludityanisiweyo luvala imingxuma ngaphakathi kwebhanti, lunika iCordweave uphawu lwayo loxinaniso oluphezulu kunye nomphezulu osicaba.

Ngokunikezela ngomphezulu othe tyaba onendawo encinci evulekileyo, iCordweave lukhetho oludumileyo lwezicelo ezahlukeneyo njengebhotile yokubhaka iimveliso ezincinci zesnack.ICordweave ithandwa kakhulu kwizicelo zokubhaka njengoko ulwakhiwo lwayo oluxinana kakhulu luqinisekisa ukuhanjiswa kobushushu okufanayo kwimveliso.

I-Cordweave ibonelelwa ngokuqhelekileyo kwiBanga le-304 leNsimbi engenasici kunye nentsimbi ye-carbon ephezulu;nangona kunjalo ezinye izixhobo ziyafumaneka xa ziceliwe.Idrayivu isetyenziswa ngokusetyenziswa kweerola zokukhuhlana, kunye nokwahluka komphetho wekhonkco kufumaneka ngesicelo esikhethekileyo.Kwizicelo ezifuna ukuphakama kwemveliso okanye ukwahlula, iCordweave inokubonelelwa ngeenqwelomoya ezinqamlezayo kunye neepleyiti ezisecaleni ezithe ngqo kwiimfuno zakho.

Ezinye iiNkqubo eziKhethekileyo zesimbo sebhanti

- Ukuphathwa kwerayisi

- I-Swarf Conveyors

- Ukunyangwa koBushushu kwiiFasteners ezincinci

- Ikhethini lesithando somlilo

- Sintering of Metal Metal Components

- Electro-Pating

- Iitheyibhile zokuqokelela

- Ukomisa Imbewu

I-Standard Cordweave (CORD)

Indibano eqhelekileyo ibandakanya ukutshintshiselana kweekhoyili zesandla sasekhohlo nasekunene kunye nekhoyili nganye enxibelelana nelandelayo ngenani leingcingo ezinqamlezayo ngekhoyili nganye.Ukungeniswa kweingcingo ezinqamlezileyo ezongeziweyo ngekhoyili nganye kuvumela ukuvala i-meshing yeekhoyili ezikufutshane kuzo zombini ububanzi kunye nobude.Ngokudityaniswa kwamabhanti eCordweave kungafuneka ukuba kunikezelwe iingcingo ezinqamlezileyo ngohlobo olumnqamkileyo (ngokweBalanced Spiral weave belts) ukuqinisekisa ukufuya kweengcingo zekhoyili.Kule fomati zombini i-coil kunye neengcingo ezinqamlezayo zecandelo elingqukuva.

Indlela yokuchongwa kwekhowudi yebhanti

Ezinye iindlela ze-Flat Wire Coil

Iinkcukacha zomesh zikwafumaneka ngeengcingo zekhoyili ezenziwe kusetyenziswa ucingo olusicaba.Ezi ndlela ziluncedo kakhulu ekufumaneni indawo engaphezulu xa uphethe iimveliso ezincinci zesiseko.Xa uchonga ucingo lwekhoyili kubalulekile ukuqinisekisa imilinganiselo yecandelo lomnqamlezo.

Ukufumaneka komda

Welded Edge

Ngenxa yokuvaleka kwe-meshing yazo zombini i-crimp kunye nocingo olunqamlezayo, i-welded luhlobo olufumanekayo lokugqitywa komphetho.

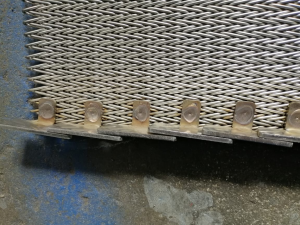

Umphetho wekhonkco oqhutywayo oKhethekileyo uMnatha

Olu hlobo lwebhanti lubandakanya umnatha osisiseko ongentla kodwa lufakelwe ngokukodwa imiphetho yekhonkco ukuqinisekisa ukuqhuba okuqinisekileyo kunye nokulandela umkhondo.Ngale ndibano ikhonkco lomphetho yindawo yokuqhuba kunye nomnatha otsalwa kwisekethe.Inqunyelwe kuluhlu oluncinci lweenketho zemesh kwaye kwiimeko ezininzi zibandakanya iikhoyili ezandisiweyo kwindawo yokujoyina intonga.Ngenxa yendlela yokudibanisa eli bhanti lingaphantsi kwezoqoqosho kunesitayela esiqhutywa yi-friction.

Iindlela zokuqhuba

Ukukhuhlana Kuqhutywa

Friction Drive Circuit elula

Eyona ndlela ixhaphakileyo yokuqhuba yintsimbi ecacileyo i-parallel driven roller system.Le nkqubo ixhomekeke ekudibaneni kwe-friction phakathi kwebhanti kunye ne-roller ukuqinisekisa ukuqhuba ibhanti.

Iiyantlukwano zolu hlobo lwe-drive ziquka ukulahlwa kwe-roller ngezinto ezifana nerabha, i-friction brake lining (ubushushu obuphezulu), njl njl. ubomi obuluncedo bebhanti.

I-Friction Drive Snub Pulley Circuit

Special Chain Edge Drive

Le ndlela isebenzisa ikhonkco elikhethekileyo eliqhutywa ngomnatha kunye namatyathanga aqhutywa ngamatyathanga e-sprockets abekwe kwi-drive kunye neeshafti ezingasebenziyo ukuze zilungelelaniswe nezi tyathanga.Iikhoyili ezikhethekileyo eziphakamileyo zingafuneka kwiindawo ezinqamlekileyo kunye nokongezwa okunokwenzeka kweengcingo zokuzalisa kufuneka ukuba imveliso ibe yincinci - jonga umfanekiso ongezantsi.

Iinkcukacha ezifumanekayo

Le theyibhile ingezantsi sisicatshulwa semeshes ezikhoyo kwaye ibonisa ezona nkcukacha ziqhelekileyo:

| Ikhowudi yenkcazo. | I-Coil Pitch kububanzi | Coil Wire Dia. | Cross Wire Pitch Down Ubude | Cross Wire Dia. | Inani leeNcingo ezinqamlezileyo ngeKhoyili nganye. |

| I-CORD3 | 5.08 | 1.22 | 3.05 | 1.22 | 3 |

| I-CORD4 | 11.29 | 2.03 | 4.35 | 2.03 | 4 |

| I-CORD4 | 10.16 | 2.03 | 5.08 | 2.64 | 4 |

| I-CORD4 | 4.24 | 0.91 | 2.24 | 1.22 | 4 |

| I-CORD4 | 8.47 | 1.63 | 3.63 | 1.63 | 4 |

| I-CORD4 | 6.35 | 1.22 | 2.82 | 1.22 | 4 |

| I-CORD5 | 8.71 | 1.6 x 1.3* | 3.39 | 1.63 | 5 |

Yonke imilinganiselo kwiimilimitha (mm).

*Ubungakanani obuqhelekileyo.

Iinkcukacha ezininzi ziyafumaneka.Nceda uqhagamshelane neeNjineli zethu zoThengiso lobuGcisa ngolwazi olungakumbi.

Ezinye iiNkqubo eziKhethekileyo zesimbo sebhanti

- Ukuphathwa kwerayisi

- I-Swarf Conveyors

- Ukunyangwa koBushushu kwiiFasteners ezincinci

- Ikhethini lesithando somlilo

- Sintering of Metal Metal Components

- Electro-Pating

- Iitheyibhile zokuqokelela

- Ukomisa Imbewu

Ukufumaneka kweMathiriyeli esemgangathweni (umnatha kuphela)

| Izinto eziphathekayo | Obona bushushu bokusebenza ngocingo °C |

| Intsimbi yeCarbon (40/45) | 550 |

| Intsimbi eGalvanized Mild | 400 |

| IChrome Molybdenum (3% Chrome) | 700 |

| 304 iStainless Steel (1.4301) | 750 |

| 321 iStainless Steel (1.4541) | 750 |

| 316 iStainless Steel (1.4401) | 800 |

| I-316L yeNtsimbi engagqwali (1.4404) | 800 |

| 314 iStainless Steel (1.4841) | 1120 (Kuphephe ukusebenzisa kwi-800-900 ° C) |

| 37/18 Nickel Chrome (1.4864) | 1120 |

| 80/20 Nickel Chrome (2.4869) | 1150 |

| I-Inconel 600 (2.4816) | 1150 |

| I-Inconel 601 (2.4851) | 1150 |

Phambi kokuba wenze ukhetho lwezicelo zobushushu obuphezulu dibana neeNjineli zethu zoThengiso lobuGcisa ngelona bakala lifanelekileyo locingo lwesicelo njengoko amandla ocingo ehla kumaqondo obushushu aphezulu.