isicelo

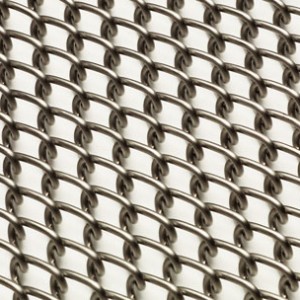

I-Balanced Spiral mesh inoyilo olulula kodwa olusebenzayo, olwakhiwe ngokutshintshana kweekhoyili ezijiyileyo ngasekhohlo nasekunene.Ezi zikhonkwane zibanjwe ngokudibanisa i-crimp rods ezihamba ngobubanzi bebhanti.Imiphetho yebhanti inokunikwa okanye i-welded okanye nge-knuckled selvedge.

I-Balanced Spiral izuza iimpawu zayo zokulandelela ezibalaseleyo ngokusebenzisa ipateni etshintshanayo ethintela ibhanti ekubeni litsalele kwicala elinye.Ukunyakaza kwe-lateral ngaphakathi kwebhanti kuncitshiswa ngokusetyenziswa kweentonga ezinqamlekileyo ezibamba i-coil nganye ejikelezayo.

I-Balanced Spiral ixhaphake ngokubonelelwa njengebhanti yokuqhuba i-friction-drive;Nangona kunjalo i-meshes ezithile zinokubonelelwa njenge-Positive-Drive, ivumela ii-sprockets ukuba zidibanise ne-belt mesh.Kungenjalo, sinokubonelela nge-Balanced Spiral kunye nemiphetho yekhonkco kwizicelo zomthwalo ophezulu.

I-Cross-Flights kunye ne-Side Plates ziyafumaneka kwizicelo ezithambekele okanye iimfuno zokwahlula imveliso.Inkampani yeBhanti yocingo ikwabonelela ngokubhantisa okuBalanced eBalanced Spiral, ukulungiselela izicelo ezinomthwalo ophakamileyo ngokukodwa kunye/okanye kwiimveliso ezifuna indawo yokuvula emxinwa kunokuba kunokwenzeka ngamabhanti ajikelezayo alungeleleneyo.

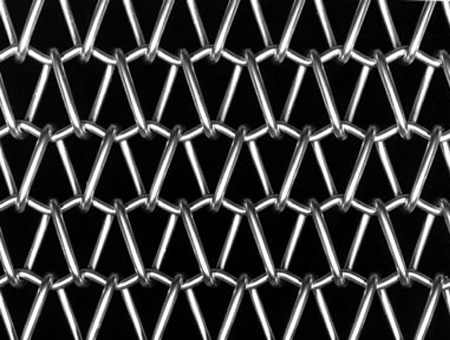

I-Spiral eBalanced esemgangathweni (BS)

Indibano ibandakanya iikhoyili ezitshintshayo zesandla sasekhohlo nasekunene kunye nekhoyili nganye enxibelelana nelandelayo ngocingo olunqamlezileyo.

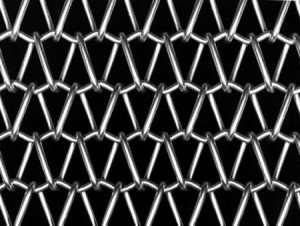

I-Double Balanced Spiral (DBS)

I-double balanced assembly iyafana ne-standard balanced spiral kodwa isebenzisa i-coil pairs ze-intermeshing ye-handing nganye kwaye idibanise ngocingo olunqamlezileyo olunepere ezidibanisayo ezidibanisa iikhoyili zesandla ezichaseneyo kwipatheni ephindayo ukuhla ngobude.Esi simbo sivumela ukuphonswa ngokusondeleyo kweekhoyili kububanzi bokuphatha imveliso encinci.

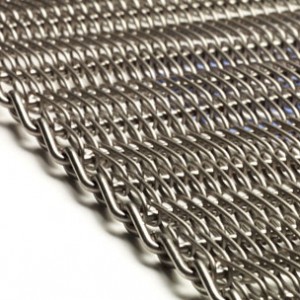

UkuPhuculwa kwe-Balanced Spiral (IBS)

Ukwakheka kweli bhanti kuyafana “neStandard Balanced Spiral” kodwa kusetyenziswa ucingo oluthe tye olunqamlezileyo olunekhoyili enye edibanisayo kwipateni ephindayo yesandla sasekhohlo/sasekunene ukuhla ngobude.Le ndibano ivumela ukuphoswa ngokusondeleyo kweekhoyili enye kububanzi bokuphatha imveliso encinci.

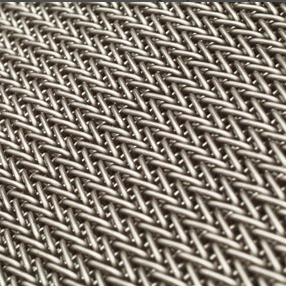

UkuPhuculwa kwe-Double Balanced Spiral (IDBS)

Ulwakhiwo lwelibhanti luyafana ne “Double Balanced Spiral” kodwa lisebenzisa ucingo oluthe tye olunqamlezileyo olunamaqhina aphindwe kabini adityanisiweyo kwisandla ngasinye esidityanisiweyo ngocingo oluthe tye olunqamlezileyo kwipatheni ephindayo yesandla sasekhohlo/esokunene sekhoyili ukuhla ngobude.Le ndibano ivumela ukuphonswa ngokusondeleyo kweekhoyili kububanzi bokuphatha imveliso encinci.

Ukufumaneka komda

I-Welded Edge (W) - i-mesh kuphela

Lo ngowona mphetho uxhaphakileyo kunye nowoqoqosho.Ngokudibanisa i-coil kunye ne-crimp ingcingo akukho ziphelo zocingo ezisikiweyo.

I-Laddered Edge (LD) - i-mesh kuphela

Ngaphantsi kwesiqhelo kunomphetho odityanisiweyo umphetho weleli udla ngokusetyenziswa apho i-welds ayinqweneleki kwisicelo.Kwakhona kukhetho kwizicelo apho izibonelelo ze-welding zingekho.Umphetho webhanti ugudile kwaye uvumela ukuguquguquka ngakumbi komphetho webhanti.Ikwasebenza ngokufanelekileyo kwizicelo zobushushu obuphezulu njengoko umphetho weleli ungekho phantsi koxinzelelo olusebenzayo olusetyenziswayo kwaye ngoko ke awufanelwanga kukuqhekeka.Ngokubanzi oku kugqitywa komphetho kufumaneka kuphela kwimeshes ezinocingo olukhulu lwecrimp pitch ezantsi ngobude.

Umda weHook (U) - umnatha kuphela

Kwakhona okungaqhelekanga kunohlobo lwe-welded edge edge ye-hook idla ngokusetyenziswa apho i-welds ayinqweneleki kwisicelo.Kwakhona kukhetho kwizicelo apho izibonelelo ze-welding zingekho.Umphetho webhanti ugudile kwaye uvumela ukuguquguquka ngakumbi komphetho webhanti.Ngokubanzi oku kugqitywa komphetho kufumaneka kuphela kwimeshes ezinocingo olukhulu lwecrimp pitch ezantsi ngobude.

Umphetho wekhonkco oqhutywa ngomnatha

Kunye nesiphelo se-mesh edge engentla le meshes inokuqhutywa ngamatyathanga asecaleni kusetyenziswa izibonda ezinqamlezileyo ezifumaneka kwiikhoyili zemesh kwaye emva koko ngamatyathanga kwincam yomnatha.Iindidi zokugqitywa kweentonga ezinqamlezileyo kumphandle wekhonkco elisecaleni zezi zilandelayo:

Ngewasha edibeneyo

Esi sesona simbo sixhaphakileyo nesinoqoqosho sokugqiba kwibhanti ephethe ikhonkco kwaye siquka i-mesh esembindini ethwalwa ngesixokelelwano ngamatyathanga asemacaleni aneentonga zomthuthi ezinqamlezayo kuzo zombini i-mesh kunye ne-edge chain.Iintsimbi ezinqamlezileyo zigqitywe kwincam yekhonkco yangaphandle ngewasha edityanisiweyo

NgePin yeCotter kunye neWasha

Nangona uqoqosho oluncinci olu hlobo lwendibano luvumela umthengi okanye abasebenzi benkonzo ukuba bakwazi ukubuyisela amatyathanga e-edge drive xa i-mesh kunye neentonga zisasebenza.Indibano ibandakanya i-mesh esembindini ehanjiswa kwinkqubo ngokusebenzisa amatyathanga asemacaleni aneentonga ezinqamlezileyo zokuthwala kuzo zombini i-mesh kunye ne-edge chain.Iintonga ezinqamlezileyo zigqitywe ngaphandle ngomngxuma ogrunjiweyo ukuvumela ukufakwa kwewasha kunye nephini yecotter.Ikwavumela ukutshintshwa kokulungiswa kwamacandelo ebhanti ngaphandle kwesidingo sokugaya iintloko zentonga kunye ne-weld back together.

QAPHELA: Ukuzinza okukhulu kobubanzi beentonga kwikhonkco yinto eqhelekileyo, apho kunokwenzeka, ukubonelela ngeerodi ezinqamlezileyo ezijikelwe phantsi ukuze zingene kumatyathanga asemacaleni.

Ezinye iindlela ezahlukeneyo zokugqiba komphetho wekhonkco ziquka:

- Intonga enqamlezileyo edityanisiweyo egungxulwayo ukuya kwikhonkco elimgongxo lekhonkco lekhonkco.Lo ayingomgangatho ukhethwayo kodwa unokuba yimfuneko apho ububanzi phakathi kwezakhelo ezisecaleni zokuhambisa kunye namanye amalungu olwakhiwo adala umda apho "iwasha edityanisiweyo" okanye "iwasha kunye nephini yecotter" ingenakusetyenziswa.

- Intonga enqamlezileyo edityanisiweyo egungxulwayo ngomngxuma owombiweyo kwiipleyiti zangaphakathi zekhonkco lokuhambisa.

Ngokubanzi iibhanti eziqhutywa ngamatsheyini njengoko kubonisiwe ngasentla ziyafumaneka ngezitayile ezi-2 zomphetho wekhonkco:

Ikhonkco loThutho

Ikhonkco lokuhambisa linerola encinci.Umphetho wekhonkco unokuxhaswa nokuba kukwiiplati zecala lekhonkco okanye ngendlela yesiporo esineprofayili ukuya phakathi kwamacwecwe ecala kunye nenkxaso kwi-roller okanye ngenye indlela ngaphandle kwenkxaso apho i-mesh ixhaswa kufuphi nomda.

Conveyor Roller Chain

I-Conveyor Roller Chain ine-roller enkulu.Umphetho wetyathanga emva koko unokuxhaswa kwi-engile enomphetho osicaba umcu wokunxiba kunye nerola yekhonkco ejikeleza ngokukhululekileyo ecaleni kobude bokuhambisa.

IiNkcazelo zeBhanti zeDrive

| Uhlobo lweMesh | Ikhowudi yokuchaza | Ukutyeba kweBhanti ngeNgesi (mm) | I-Lateral Pitch ye-Coil wire(mm) | Coil Wire Dia.(mm) | Ubude beCrimped Cross Wire Pitch ezantsi (mm) | I-Crimped Cross Wire Dia (mm) |

| BSW-PD | 18-16-16-16 | 7.7 | 16.94 | 1.63 | 19.05 | 1.63 |

| BSW-PD | 18-14-16-14 | 8.9 | 16.94 | 2.03 | 19.05 | 2.03 |

| BSW-PD | 30-17-24-17 | 7.3 | 10.16 | 1.42 | 12.7 | 1.42 |

| BSW-PD | 30-16-24-16 | 6.7 | 10.16 | 1.63 | 12.7 | 1.63 |

| BSW-PD | 42-18-36-18 | 6.0 | 7.26 | 1.22 | 8.47 | 1.22 |

| BSW-PD | 42-17-36-17 | 6.0 | 7.26 | 1.42 | 8.47 | 1.42 |

| BSW-PD | 42-16-36-16 | 6.4 | 7.26 | 1.63 | 8.47 | 1.63 |

| BSW-PD | 48-17-48-17 | 6.1 | 6.35 | 1.42 | 6.35 | 1.42 |

| BSW-PD | 48-16-48-16 | 6.4 | 6.35 | 1.63 | 6.35 | 1.63 |

| BSW-PD | 60-20-48-18 | 4.0 | 5.08 | 0.91 | 6.35 | 1.22 |

| BSW-PD | 60-18-48-18 | 5.2 | 5.08 | 1.22 | 6.35 | 1.22 |

| BSW-PD | 60-18-60-18 | 5.6 | 5.08 | 1.22 | 5.08 | 1.22 |

Zonke iinkcukacha zibonelelwa ngomphetho odityanisiweyo kuphela.

Ezinye iziCelo eziKhethekileyo zesimbo sebhanti:

| Ukufumaneka koMathiriyeli oMgangatho (umnatha kuphela) Isixhobo | Obona bushushu bokusebenza ngocingo °C |

| Intsimbi yeCarbon (40/45) | 550 |

| Intsimbi eGalvanized Mild | 400 |

| IChrome Molybdenum (3% Chrome) | 700 |

| 304 iStainless Steel (1.4301) | 750 |

| 321 iStainless Steel (1.4541) | 750 |

| 316 iStainless Steel (1.4401) | 800 |

| I-316L yeNtsimbi engagqwali (1.4404) | 800 |

| 314 iStainless Steel (1.4841) | 1120 (Kuphephe ukusebenzisa kwi-800-900 ° C) |

| 37/18 Nickel Chrome (1.4864) | 1120 |

| 80/20 Nickel Chrome (2.4869) | 1150 |

| I-Inconel 600 (2.4816) | 1150 |

| I-Inconel 601 (2.4851) | 1150 |